Praxair Surface Technologies Videos

1 - 47 of 47 View First 9 Results

Thermal Spray Equipment & Consumables

We work directly with you to understand your operational requirements and select the best TAFA-brand thermal spray systems, powder feeders, acoustical enclosures and more that will help you reach your goals.

SermeTel Coating Process in the Power...

We can apply a wide range of slurry coatings bonded to the substrate to provide protection to critical components in the power generation industry.

EBPVD Coating Process

Our EBPVD technology allows us to create high-performing thermal barrier coatings (TBCs) with fine columnar microstructures that are super tolerant to lateral strain.

How Praxair Services the Additive...

Praxair brings together high-purity atmospheric gases including argon and nitrogen with fine, spherical metal powders to meet the needs of additive manufacturing processes like no other supplier.

Cold Spray Coating Process

Our proprietary LOXPlate™ cold spray process produces high-density low-oxygen coatings at high deposition rates and is ideally suited for restoring your worn components.

How Metal 3D Printing Works

Leading producer of metal powders for additive manufacturing, Praxair Surface Technologies, shows you how 3D metal printing works. Layer by layer. From design to modeling to printing in plastic and metal to validating the final printed product.

SermeTel Coating in the Oil and Gas Industry

We can apply a wide range of slurry coatings bonded to the substrate to provide protection to critical components in the oil and gas industry.

How Metal 3D Printing Works

See how 3D metal printing works. Layer by layer. From design to modeling to printing in plastic and metal to validating the final printed product.

Research and Development

No matter what challenges you are facing, our team is committed to delivering the best solution. The Praxair Surface Technologies R&D team is made up of dedicated engineers and technologists who are working together towards a single goal:...

PtAl Coating Process

Platinum aluminide (PtAl) is the coating choice for many aviation gas turbine hot section airfoils.

Titanium Powders for Additive Manufacturing

Praxair Surface Technologies is making some of the largest batches of fine titanium powder for additive manufacturing in the world via its close-coupled titanium atomizer that can produce 10x the yields vs. traditional atomization.

Fluoropolymer Coating Process

Fluoropolymer coatings can protect against salt corrosion for components exposed to offshore atmospheric and subsea environments.

HVOF Coating Process Auto

Watch Praxair’s patented wear-control coating be applied via the high-velocity oxy fuel (HVOF) process to aluminum wheels.

LPPS Coating Process

LPPS is plasma spraying under low-pressure conditions. It offers all the advantages of plasma spray while delivering the inert environment to produce very dense coatings with ultra-low oxide content.

HVOF Coating Process Ball Valves

Our high-velocity oxy fuel (HVOF)-applied coatings are hard and wear-resistant to impede erosive and abrasive wear and corrosive attack, and deliver a tight seal every time to help you achieve zero leakage.

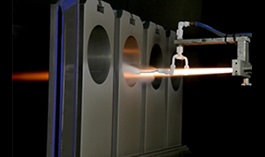

D-Gun Coating Process Aviation

Watch our proprietary detonation gun (D-Gun) thermal process—the leading solution for parts that require extraordinary mechanical and wear properties—in action as it applied a coating to an aviation engine blade.

Tribomet Process

Our Tribomet abrasive coatings allow for turbocharger nozzle designs that reduce the gap between the stator and rotor to improve fuel efficiencies.

TiN Coating Process

We use cathodic arc physical vapor deposition (CAPVD) to deposit titanium nitride as a monolayer or multilayer coating to precision parts.

HVOF Coating Process Gates

Our hard surface LW-45 and GV-50H coatings applied via the high-velocity oxy fuel (HVOF) process resist corrosion, erosion, abrasion, sliding wear and galling.

HVOF Coating Process Rotors

We apply carbide coatings to progressive cavity rotors via our high-velocity oxy fuel (HVOF) thermal spray process to ensure longer-life protection and improved performance in the field.

Discovery Lab

It all starts in the Discovery Lab where we develop next-generation coatings for ultimate protection.

Corrosion Lab

Here we use a salt fog test to ensure parts used in industries such as oil and gas and power generation are protected against corrosion.

Making More Possible in Printing and...

For more than a quarter century, press manufacturers, printers and converters around the world have turned to Praxair Surface Technologies for ceramic laser-engraved anilox rolls and sleeves that fit their application and offer longer service...

Making More Possible in Power Generation

Every day a gas turbine is not generating power, you lose revenue. That's why Praxair Surface Technologies develops coatings to improve component lifespans, lower replacement costs and extend the time between service outages.

Metallurgical Lab

Each of our coating and manufacturing plants contains a Metallurgical Lab where coating samples are tested to ensure they meet customer specifications prior to going into production.

1 - 47 of 47 View First 9 Results